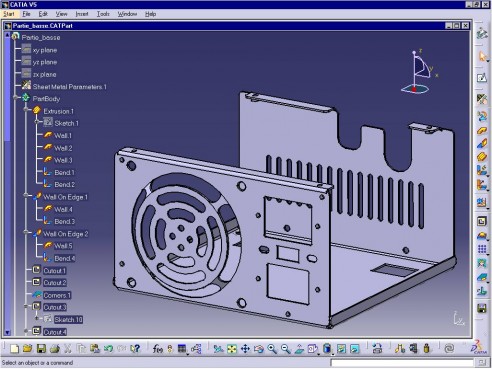

The generative sheetmetal design workbench is a new generation product offering an intuitive and flexible user interface.

Difference between sheet metal design and generative sheet metal design.

Hot rolled steel sheets are used in fabrication work where aesthetics and quality are not very important.

Worthy hardware co ltd 86 769 89919645 86 769 89918145 86 769 81500427.

It provides an associative feature based modeling making it possible to design sheet metal parts in concurrent engineering between the unfolded or folded part representation.

Generative sheet metal design overview.

Generative sheet metal parameters overview.

For example railway track automotive frames structural frames low accuracy sheet metal parts etc.

For example it would generally struggle with most curvatures let alone double curvatures.

You can also verify sheet metal features or the entire part against these standards.

Whereas cold rolled steel sheets are used for precision and quality fabrication work for example consumer electronics and telecom products metal furniture automobile industry etc.

Center to center distance between two holes minimum center to center distance between two holes in sheet metal parts is required to avoid metal distortion deformation and fracturing.

Parameter standards help you enforce standard techniques and practices used when creating sheet metal features by simplifying how one defines the feature parameters therefore streamlining the design process.

Additionally in the new versions the generative sheet design toolbar is replaced with several toolbars this provides logical grouping of functions for enhanced accessibility.

Hope the explanation on this will help you understand them well in the future.

To sum up the main difference between machining and sheet metal fabrication are the production process material shape and their precision.

Aerospace sheet metal design in catia v5.

Hi guys my name is rafet from istanbul turkey could anyone tell me what the difference between generative sheet metal design and sheet metal desing.

Recommended minimum distance between hole slot edge to bend in sheet metal design is three times the sheet thickness plus bend radius.